Euclid Chemical, based in Cleveland, has been supplying the construction industry with products to improve the strength, appearance, and usability of concrete since 1910. Now a large, multi-national corporation, Euclid Chemical’s main offices are in a two-story, 15,000 square foot building that also contains laboratories where they develop products ranging from sealants to micro synthetic fibers.

Until recently, the building relied upon an aging VAV system with terminal reheat to keep their offices comfortable and to maintain environmental conditions in the laboratories. Even when new, records showed the system had not performed as designed. This inadequate performance was compounded by cumulative effects of years of normal wear and tear along with questionable modifications.

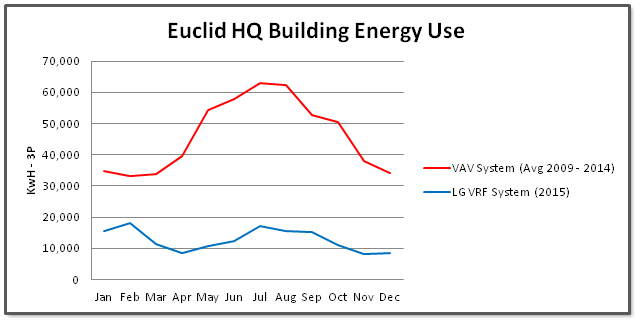

Ultimately, the system no longer kept people comfortable, broke down frequently and was incredibly inefficient. After analyzing the utility bills, Joe Messer, Director of Engineering for Euclid Chemical, realized that building had an average annual energy use of 38 kWh/square foot -- over twice the average consumption for offices in the same geographic area, and more than most of Euclid’s manufacturing facilities. Messer knew Euclid Chemical needed to upgrade to a dependable and efficient system that would meet their needs for years to come.

CRITERIA:

The building housed both office areas and laboratories, so throughout the facility the system had to provide individual temperature control which, at any given time, may require both heating and cooling in different areas.

In the lab, the system also had to account for the unique challenge of quickly adapting to rapidly changing make-up air requirements as laboratory fume hoods started and stopped. It also had to work in the Ohio climate where the outdoor temperature ranged from sub-zero weather in the winter to humid high-90’s in the summer. But above all else, the system had to have a manageable upfront cost and an attractive payback to the Euclid financial team.

SOLUTION:

Messer began the process of finding a new solution and reached out to trusted engineer Andy Culberson of Geisel Heating and Cooling. Culberson identified VRF (Variable Refrigerant Flow) technology as the optimum solution, and reached out to Peter Eno of Refrigeration Sales Corporation to collaborate on a best-in-class solution based on VRF technology from LG Electronics. Together they designed a system around LG Multi-V heat recovery systems.

The bulky 50 ton DX unit on the roof was replaced by a pair of small air-cooled outdoor units on the ground, and the VAV boxes inside the building were replaced with LG’s concealed high-static VRF indoor units. To account for the need for ventilation air and makeup air when the laboratory fume hoods were in use, a small makeup air unit with a water heating coil was added to provide ventilation air at a high-static pressure to the LG VRF indoor units. Since this was 100 percent outdoor air, the airflow could be adjusted to precisely meet the ventilation requirements as they changed. The LG Multi V is a heat recovery system, so it can heat the zones that need it while cooling others simultaneously which delivers precise temperature in all parts of the facility regardless of Ohio’s weather, including subzero winters.

After they presented the system proposal, everyone at Euclid Chemical was sold on the concept. Based on the problems and poor performance of the existing system, Messer conservatively estimated the new system would cut their utility bills by 40 percent. What’s more, they could reuse the existing distribution and supply ductwork, reducing upfront installation costs, which further sold the financial team.

RESULTS:

Once construction was completed, the system performance exceeded expectations, according to Messer. After implementation, the facility saw a 70 percent annual energy reduction compared to the average of the previous five years. (See graph.)

Equally important, the new system provides a quiet, comfortable environment for people to work. “Employees have definitely noticed an improvement in comfort,” said Messer. “This allowed us to focus on our core business instead of worrying about HVAC.” He is currently evaluating other buildings within the Euclid portfolio and, not surprisingly, he’s considering LG VRF solutions.

Related Stories

| Jan 11, 2014

Getting to net-zero energy with brick masonry construction [AIA course]

When targeting net-zero energy performance, AEC professionals are advised to tackle energy demand first. This AIA course covers brick masonry's role in reducing energy consumption in buildings.

| Jan 6, 2014

Green Building Initiative names Jerry Yudelson as new President

The Green Building Initiative announced today that it has named Jerry Yudelson as its president to accelerate growth of the non-profit and further leverage its green building assessment tools, including the highly recognized Green Globes rating system.

| Jan 6, 2014

An interview with Jerry Yudelson, President, The Green Building Initiative

Green building consultant Jerry Yudelson has been named President of the Green Building Initiative and the Green Globes rating program. BD+C's Robert Cassidy talks with Yudelson about his appointment and the future of Green Globes.

| Jan 2, 2014

Measuring whole building energy use among big changes in LEED v4

A new prerequisite in LEED v4 calls for each project to measure whole building energy use, and then share that data with USGBC.

| Dec 31, 2013

Top 10 blog posts from 2013

BD+C editors and our contributors posted hundreds of blogs in 2013. Here's a recap of the most popular topics. They include valuable lessons from one of the first BIM-related lawsuits and sage advice from AEC legend Arthur Gensler.

| Dec 20, 2013

Can energy hogs still be considered efficient buildings? Yes, say engineers at Buro Happold

A new tool from the engineering firm Buro Happold takes into account both energy and economic performance of buildings for a true measure of efficiency.

| Dec 17, 2013

Nation's largest net-zero K-12 school among winners of 2013 Best of Green Schools award

The Lady Bird Johnson Middle School in Irving, Texas, was named a winner of USGBC's annual award, along with nine other schools, individuals and communities working toward the common goal of healthy, high-performing learning places.

| Dec 10, 2013

16 great solutions for architects, engineers, and contractors

From a crowd-funded smart shovel to a why-didn’t-someone-do-this-sooner scheme for managing traffic in public restrooms, these ideas are noteworthy for creative problem-solving. Here are some of the most intriguing innovations the BD+C community has brought to our attention this year.

| Nov 27, 2013

LEED for Healthcare offers new paths to green

LEED for Healthcare debuted in spring 2011, and certifications are now beginning to roll in. They include the new Puyallup (Wash.) Medical Center and the W.H. and Elaine McCarty South Tower at Dell Children’s Medical Center of Central Texas in Austin.

| Nov 27, 2013

University reconstruction projects: The 5 keys to success

This AIA CES Discovery course discusses the environmental, economic, and market pressures affecting facility planning for universities and colleges, and outlines current approaches to renovations for critical academic spaces.