The U.S. Energy Department wants wind power to provide at least 20% of the nation’s energy needs by 2030, compared to 3.5% in 2013. Until recently, manufacturers have not been able to replicate on a sufficiently large scale the stress forces that offshore wind turbines must be able to endure.

In 2009, DOE’s Office of Energy Efficiency & Renewable Energy awarded $45 million—its largest single wind-power grant—to Clemson University to build a facility capable of full-scale, highly accelerated testing of the next generation of wind turbine drive-train technology.

The Clemson University Restoration Institute converted a decommissioned Navy warehouse in North Charleston, S.C., into the SCE&G Energy Innovation Center, where such testing is now feasible. The facility also houses Duke Energy’s 15-megawatt eGrid simulator, which tests and validates the impact of electric equipment turbines on the nation’s aging electrical grid.

The project’s sheer magnitude made it a design, engineering, and construction feat. Much of the equipment installed in the facility had never been used before. With design teams and suppliers in the U.S. and Europe, a considerable degree of planning and coordination was required.

PROJECT SUMMARY

GOLD AWARD

Clemson University SCE&G Energy Innovation Center

North Charleston, S.C.BUILDING TEAM

Submitting firm: Choate Construction Co. (GC/CM)

Owner: Clemson University Restoration Institute

Architect/MP engineer: Davis & Floyd

Structural/electrical engineer: AEC EngineeringGENERAL INFORMATION

Project size: 82,264 sf

Construction cost: $37.3 million

Construction period: September 2011 to February 2014

Delivery method: CM at risk

“This project took the meaning of complexity to a whole new level,” says Drew Clark, Senior Project Manager for Clark Construction, a Building Team Awards judge. “When you understand the coordination, logistics, and extreme tolerances—fractions of an inch—required to support the test equipment, you get the sense that they were building something of a Swiss watch, not just a building. Very impressive.”

To meet seismic code requirements, over 900 steel H and concrete piles, ranging in length from 40 to 85 feet and weighing more than 400 pounds, were driven—the equivalent of nine miles of pilings.

The testing equipment included 7.5- and 15-MW hydraulic dynamometers that can replicate the severe rotating and bending forces exerted on the drive trains by 300-foot-long wind turbine blades at sea. Controlling these forces required two testing bays with dynamic independent foundations that could accommodate the massive torque of the testing system, plus the weight of the rigs. A single gearbox weighs 341 tons, or the equivalent of a Boeing 747.

Because the test rigs were so deep and embedded with congested rebar—the 15-MW foundation was 42 feet wide by 100 feet long by 15 feet deep—concrete couldn’t be pumped and vibrated. The Building Team specified self-consolidating concrete with chemical viscosity modifiers that allowed the concrete to flow throughout the rebar and formwork without the need for vibration. The concrete was poured in a single, continuous 12-hour run for each test rig.

There’s over 900 tons of rebar in the test bed foundations, bent to nearly micron levels. The Building Team used BIM modeling to identify 8,500 conflicts in the foundation before construction.

The Building Team also designed an anchor system so turbines could be moved around and repositioned during testing. Four hundred anchor sleeves and 15 assembled arrays were installed; each was measured during fabrication, assembly, setting, and as-built condition.

One anchoring assembly is the 15-MW Load Application Unit (LAU), also known as “Death Star.” The LAU ring, which had to be transported 250 miles in four pieces to the site, required 96 6.5-foot-long tubes. In full field operation, one million pounds of steel components will be cantilevered off of the ring and its surrounding concrete structure.

Its dynamometers require 22.5 MW of electricity to operate at full capacity, or enough to power 15,000–25,000 homes per year. The facility recovers about 80% of that energy, resulting in energy cost savings of 60.3% and contributing to the project’s LEED Gold certification. Photo: Ryan Manchester, Clear Sky Images

Its dynamometers require 22.5 MW of electricity to operate at full capacity, or enough to power 15,000–25,000 homes per year. The facility recovers about 80% of that energy, resulting in energy cost savings of 60.3% and contributing to the project’s LEED Gold certification. Photo: Ryan Manchester, Clear Sky Images

Crews laid down 900 tons of rebar in the test bed foundations. Specialty concrete was poured in a single run to make sure the concrete penetrated the rebar without the use of vibration equipment.

Crews laid down 900 tons of rebar in the test bed foundations. Specialty concrete was poured in a single run to make sure the concrete penetrated the rebar without the use of vibration equipment.

Related Stories

Codes and Standards | Apr 8, 2024

Boston’s plans to hold back rising seawater stall amid real estate slowdown

Boston has placed significant aspects of its plan to protect the city from rising sea levels on the actions of private developers. Amid a post-Covid commercial development slump, though, efforts to build protective infrastructure have stalled.

Sustainability | Apr 8, 2024

3 sustainable design decisions to make early

In her experience as an architect, Megan Valentine AIA, LEED AP, NCARB, WELL AP, Fitwel, Director of Sustainability, KTGY has found three impactful sustainable design decisions: site selection, massing and orientation, and proper window-to-wall ratios.

Brick and Masonry | Apr 4, 2024

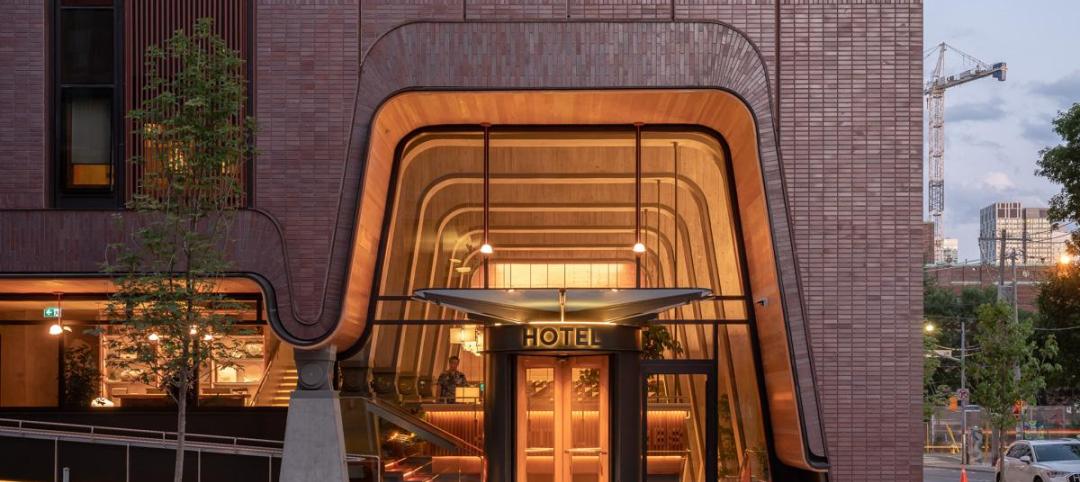

Best in brick buildings: 9 projects take top honors in the Brick in Architecture Awards

The Ace Hotel Toronto, designed by Shim-Sutcliffe Architects, and the TCU Music Center by Bora Architecture & Interiors are among nine "Best in Class" winners and 44 overall winners in the Brick Industry Association's 2023 Brick in Architecture Awards.

Retail Centers | Apr 4, 2024

Retail design trends: Consumers are looking for wellness in where they shop

Consumers are making lifestyle choices with wellness in mind, which ignites in them a feeling of purpose and a sense of motivation. That’s the conclusion that the architecture and design firm MG2 draws from a survey of 1,182 U.S. adult consumers the firm conducted last December about retail design and what consumers want in healthier shopping experiences.

Healthcare Facilities | Apr 3, 2024

Foster + Partners, CannonDesign unveil design for Mayo Clinic campus expansion

A redesign of the Mayo Clinic’s downtown campus in Rochester, Minn., centers around two new clinical high-rise buildings. The two nine-story structures will reach a height of 221 feet, with the potential to expand to 420 feet.

Sports and Recreational Facilities | Apr 2, 2024

How university rec centers are evolving to support wellbeing

In a LinkedIn Live, Recreation & Wellbeing’s Sadat Khan and Abby Diehl joined HOK architect Emily Ostertag to discuss the growing trend to design and program rec centers to support mental wellbeing and holistic health.

Architects | Apr 2, 2024

AE Works announces strategic acquisition of WTW Architects

AE Works, an award-winning building design and consulting firm is excited to announce that WTW Architects, a national leader in higher education design, has joined the firm.

Office Buildings | Apr 2, 2024

SOM designs pleated façade for Star River Headquarters for optimal daylighting and views

In Guangzhou, China, Skidmore, Owings & Merrill (SOM) has designed the recently completed Star River Headquarters to minimize embodied carbon, reduce energy consumption, and create a healthy work environment. The 48-story tower is located in the business district on Guangzhou’s Pazhou Island.

K-12 Schools | Apr 1, 2024

High school includes YMCA to share facilities and connect with the broader community

In Omaha, Neb., a public high school and a YMCA come together in one facility, connecting the school with the broader community. The 285,000-sf Westview High School, programmed and designed by the team of Perkins&Will and architect of record BCDM Architects, has its own athletic facilities but shares a pool, weight room, and more with the 30,000-sf YMCA.

Market Data | Apr 1, 2024

Nonresidential construction spending dips 1.0% in February, reaches $1.179 trillion

National nonresidential construction spending declined 1.0% in February, according to an Associated Builders and Contractors analysis of data published today by the U.S. Census Bureau. On a seasonally adjusted annualized basis, nonresidential spending totaled $1.179 trillion.