In the race to develop tech tools to make meaningful efficiency gains in the complex, often-messy commercial construction process, the R&D team at Turner Construction Company has remained keenly focused on one goal: simplicity.

New tools and processes must be easy to execute, by almost anyone in the field, and take advantage of readily accessible data—photos, video—to solve real-world problems. Leave the mind-bogglingly complicated data analysis work to computer scientists like Mani Golparvar-Fard.

Turner’s multi-year partnership with Golparvar-Fard, an Assistant Professor of Engineering and Computer Science at the University of Illinois at Urbana-Champaign, and a former Turner field engineer, has led to the development of breakthrough analytics tools that use structure from motion (SfM) algorithms to make sense of a job site, in real time, using high-definition photos and video.

Now, the technology is being piloted in the field, on the Sacramento Kings’ new 17,500-seat Golden 1 Center project, currently under construction in downtown Sacramento, Calif.

“Over the past 10 years, we’ve built these amazing 4D and 5D BIM models to help us plan our large commercial construction projects,” says Lincoln Wood, Regional Manager, Virtual Design and Construction, based in Turner’s Oakland, Calif., office. “But we still face the challenge of knowing what’s happening out in the field in real time.”

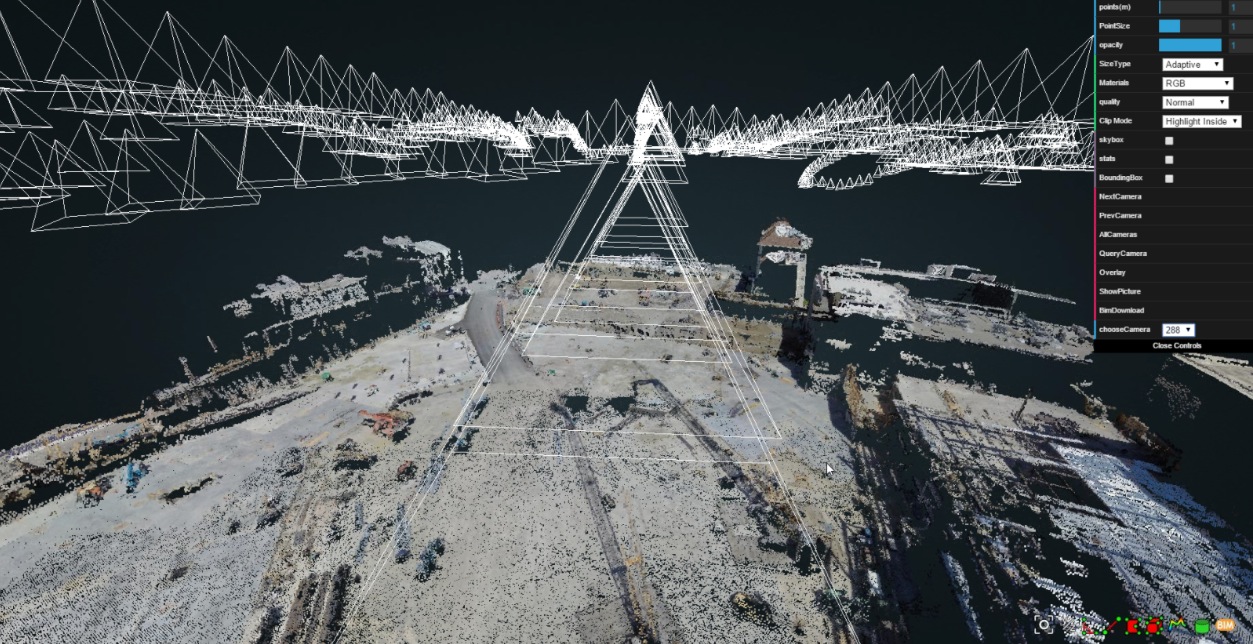

The initial phase of the pilot project involves using aerial drones (right) to document the construction progress. Once the structure goes up, the team will utilize a custom-built rover (left), as well as project engineers, to capture images and video. “The goal is to do this every day,” says Lincoln Wood, Regional Manager, Virtual Design and Construction, with Turner. “With the pilot, we have it down to a week, in time for the weekly work plan.” Courtesy Turner. Click image to enlarge.

The initial phase of the pilot project involves using aerial drones (right) to document the construction progress. Once the structure goes up, the team will utilize a custom-built rover (left), as well as project engineers, to capture images and video. “The goal is to do this every day,” says Lincoln Wood, Regional Manager, Virtual Design and Construction, with Turner. “With the pilot, we have it down to a week, in time for the weekly work plan.” Courtesy Turner. Click image to enlarge.

Using proprietary predictive visual data analytics software developed by Golparvar-Fard, the Building Team for the Golden 1 Center project is conducting near-real-time construction progress monitoring using high-resolution photos and video. The initial phase involves reality capture with an aerial drone. As the arena structure goes up, the team will also rely on a camera-equipped land rover (which will be programmed to navigate the interior spaces) and project engineers, who will use smartphones and tablets to gather photos and video.

Once collected, the visual data is stitched together using the SfM algorithm to form a point cloud. The point cloud is then overlaid atop the project’s 4D BIM model to compare and contrast what is happening in the field versus the intended result in the BIM model. (The point cloud creation and BIM overlay work occurs overnight.)

The resulting report is a color-coded 3D visual production model that provides the Building Team with a snapshot of the construction progress, and, most importantly, the areas of the job site that are at risk of falling behind schedule.

By streamlining construction progress monitoring, and providing timely reporting, Wood says the project team has a much deeper level of transparency and improved communication.

“A really good superintendent can see everything in their head; they don’t need a BIM model—it’s in their brain,” says Wood. “Unfortunately, the whole project team does not have that brain. This is a great way for the entire team to see where we are and show what we need to do in order to get back on track and improve the schedule.”

Based on the results of the job site scan and analysis, custom reports are generated for each member of the project management team, including key subcontractors, for the weekly planning meetings.

“The goal is to do this every day,” says Wood. “With the pilot, we have it down to a week, in time for the weekly work plan. We give this report to the team, showing the problem areas and the top-10 risks to the job site. It allows us to visualize and mitigate potential risks to our schedule before they happen.”

Wood says that the enhanced construction progress data may eventually be used for faster and more accurate subcontractor payments, “by removing a lot of the administrative work that happens by having to go back and forth between the job site and the office.”

It also equips the Building Team and owner with “smarter” and more-comprehensive visual documentation of the construction work, by automatically organizing and cataloging thousands of photos and video clips.

“With most jobs, the project engineers are asked to take a bunch of photographs when they’re out in the field, if they have time after their RFIs and submittals are completed for the day,” says Wood. Those images then must be uploaded to the project server, where they are stored with a random code and remain largely unorganized.

“Because our images are stitched together to create a point cloud, we have a better sense of a record of time,” says Wood.

Related Stories

BIM and Information Technology | Jul 16, 2015

BIM for O+M: New app streamlines project documentation handover process

The Building Ops app enables owners to begin operations on the first day with a turnkey maintenance and asset management solution, according to its maker, Autodesk.

BIM and Information Technology | Jul 15, 2015

Google launches open-source beacon platform: Eddystone

Though beacons usually broadcast information publicly, Eddystone has the option to communicate privately as well, which greatly expands the applications for the technology.

BIM and Information Technology | Jul 14, 2015

New city-modeling software quantifies the movement of urban dwellers

UNA for Rhino 3D helps determine the impact that urban design can have on where pedestrians go.

BIM and Information Technology | Jul 14, 2015

Nation’s first 'drone park' breaks ground in North Dakota

This is one of six testing sites around the country that are developing flight standards and evaluating the utility of drones for different tasks.

BIM and Information Technology | Jul 6, 2015

BIM/VDC training is more than learning the features

Training can be a taxing experience for both the class and the instructor. CASE's Nathan Miller offers four ways to make training more relevant to practitioners.

BIM and Information Technology | Jul 6, 2015

Researchers increase GPS precision to centimeter-accurate

A new startup is working with Samsung to develop a snap-on accessory for centimeter-accurate global positioning.

BIM and Information Technology | Jul 6, 2015

New documentary shows Legos as touchstones of creativity

The film's narrator, actor Jason Bateman, says it’s a story “about a simple toy and how its unique properties ushered in a new era of creativity for a whole generation.”

BIM and Information Technology | Jul 1, 2015

World’s first fully 3D-printed office to be produced in Dubai

A 20-foot-tall printer will be needed for the project, spewing out construction material consisting of special reinforced concrete, fiber reinforced plastic, and glass fiber reinforced gypsum.

Sponsored | BIM and Information Technology | Jun 23, 2015

Emerging technology reinvents construction principals

Gilbane discovered the anecdotal side of laser scanning pales in comparison to the dramatic ROI story.

BIM and Information Technology | Jun 23, 2015

A steel bridge in Amsterdam will be 3D printed

To complete the bridge, multi-axis industrial robots will be fitted with 3D printing tools and controlled using custom software that enables the robots to print metals, plastics, and combinations of materials.