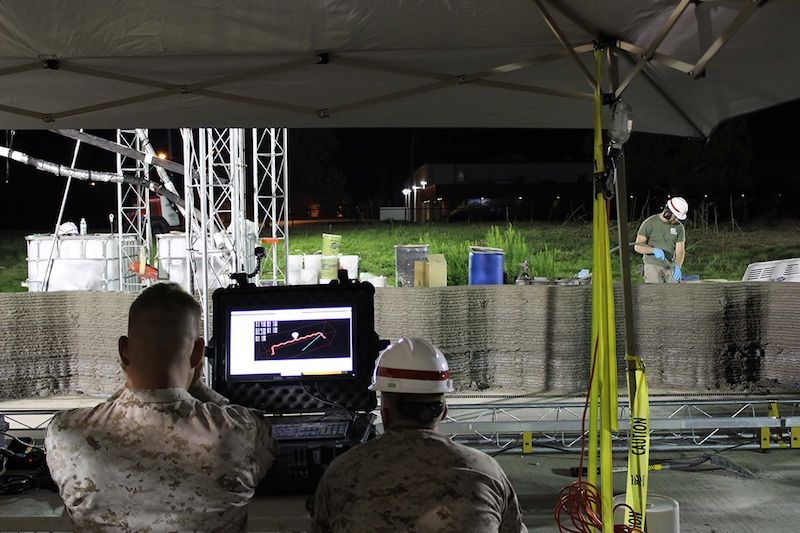

The Additive Manufacturing Team at Marine Corps Systems Command (MCSC) and Marines from I Marine Expeditionary Force recently teamed up at the U.S. Army Engineer Research and Development Center to 3D print a barracks.

The team used a computer-aided design model on a 10-year-old computer, concrete, and a 3D printer to create the 500-sf building. The job took 40 hours, but the Marines claim if there was a robot to do the mixing and pumping, the building could easily be created in one day. Typically, it takes 10 Marines five days to build a barracks out of wood.

See Also: Dubai plans to 3D print 25% of every new building by 2025

According to Capt. Matthew Friedell, AM project officer in MCSC’s Operations and Programs/G-3, nothing like this has been done before. “People have printed buildings and large structures, but they haven’t done it onsite and all at once. This is the first-in-the-world onsite, continuous concrete print,” Friedell said in a release.

Not only does using a concrete printer expedite barracks construction, but it can also help keep Marines safe. “In active or simulated combat environments, we don’t want Marines out there swinging hammers and holding plywood up. Having a concrete printer that can make buildings on demand is a huge advantage for Marines operating down range,” says Friedell.

The Marine Corps is currently staffing a deliberate urgent needs statement and concept of employment for this technology. The results of the field user evaluation will inform future requirements to give the Corps a concrete construction additive manufacturing program of record.

For more information, click here.

Related Stories

3D Printing | Jun 20, 2023

World's largest 3D-printed building completed in Florida

Printed Farms, known for completing Florida’s first permitted 3D-printed house in Tallahassee, announces the completion of the world’s largest 3D-printed building: a luxury horse barn.

3D Printing | Jun 1, 2023

World's first 3D-printed place of worship being built in India

The 3D-printed temple is set to embark on an architectural revolution in the Nation.

3D Printing | May 12, 2023

World’s first 3D-printed medical center completed

3D construction printing reached new heights this week as the world’s first 3D-printed medical center was completed in Thailand.

Sustainability | May 1, 2023

Increased focus on sustainability is good for business and attracting employees

A recent study, 2023 State of Design & Make by software developer Autodesk, contains some interesting takeaways for the design and construction industry. Respondents to a survey of industry leaders from the architecture, engineering, construction, product design, manufacturing, and entertainment spheres strongly support the idea that improving their organization’s sustainability practices is good for business.

3D Printing | Apr 11, 2023

University of Michigan’s DART Laboratory unveils Shell Wall—a concrete wall that’s lightweight and freeform 3D printed

The University of Michigan’s DART Laboratory has unveiled a new product called Shell Wall—which the organization describes as the first lightweight, freeform 3D printed and structurally reinforced concrete wall. The innovative product leverages DART Laboratory’s research and development on the use of 3D-printing technology to build structures that require less concrete.

3D Printing | Jan 12, 2022

Using 3D-printed molds to create unitized window forms

COOKFOX designer Pam Campbell and Gate Precast's Mo Wright discuss the use of 3D-printed molds from Oak Ridge National Lab to create unitized window panels for One South First, a residential-commercial high-rise in Brooklyn, N.Y.

AEC Tech Innovation | Oct 7, 2021

How tech informs design: A conversation with Mancini's Christian Giordano

Mancini's growth strategy includes developing tech tools that help clients appreciate its work.

3D Printing | Jun 29, 2021

The world’s first 3D printed school completes in Malawi, Africa

A COBOD BOD2 printer was used to create the building.

3D Printing | Nov 27, 2020

The Fibonacci House: A test case of 3D construction printing

The Fibonacci House, which we have named after Leonardo Fibonacci, the medieval Italian mathematician, illustrates the potential of 3DCP and demonstrates how a complex design and challenging logistics can be solved through pragmatic planning and 3DCP technology.

Coronavirus | Apr 15, 2020

3D printing finds its groove fabricating face shields during COVID-19 crisis

The architecture firm Krueck + Sexton is producing 100 shields for a Chicago-area hospital.