At some point in the past year or so, you have probably heard the term “hyperloop” thrown around as the future of transportation. Elon Musk first unveiled the concept of a hyperloop in 2013, Dezeen reports. Since that time, however, he open-sourced the technology and is no longer directly involved with the development.

This gave other companies, such as Hyperloop One, the opportunity to take the hyperloop from concept to reality. The company describes its hyperloop system on its website by writing, “The system uses electric propulsion to accelerate a passenger or cargo vehicle through a tube in a low pressure environment. The autonomous vehicle levitates slightly above the track and glides at faster-than-airline speeds over long distances. We eliminate direct emissions, noise, delay, weather concerns and pilot error.”

The idea of a hyperloop may seem more science fiction than fact, but it is actually grounded in reality. Hyperloop One, with the help of Danish design firm BIG, has big plans of connecting Dubai and Abu Dhabi via a hyperloop, bringing travel time between the two cities down to just 12 minutes. Riyadh would be reached in 48 minutes, Doha in 23 minutes, and Muscat in 27 minutes. The hyperloop pods that hold the passengers and their cargo will be able to reach speeds of up to 1,100 kilometers per hour.

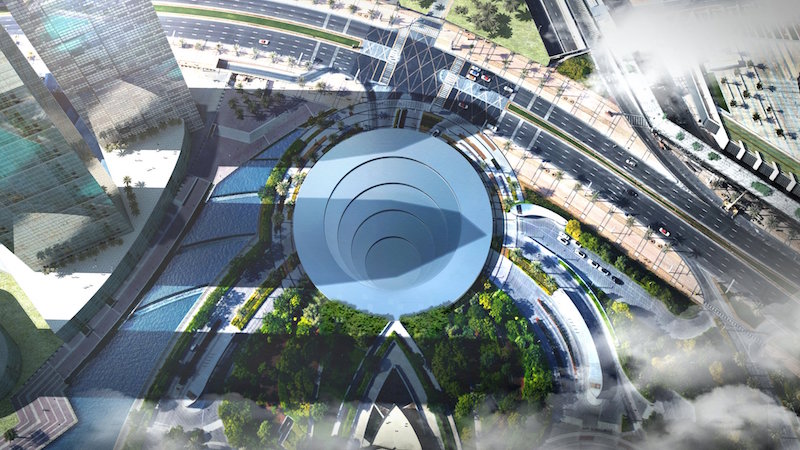

BIG’s designs show the Dubai station, dubbed the “portal” due to its sunken and circular styling, situated at the foot of the Burj Khalifa, according to the most recent information from Dezeen.

Each pod has room for six people and is loaded onto a transporter vessel attached to a chassis, although, the pods will differ with plans for specific offerings for business, lounge, and single. The pods themselves are autonomous and can leave the transporter, travel onto regular roads, and pick up passengers at any point, according to BIG.

The portal eliminates waiting halls through the use of frequent arrival and departure times.

Along with BIG, engineering firms AECOM and Arup are also working with Hyperloop One in an effort to become the first team to build a hyperloop system. Hyperloop One tested its propulsion technology earlier this year near Las Vegas and achieved speeds of 187 kilometers per hour in 1.1 seconds.

Currently, Hyperloop One’s top competitor is Hyperloop Transportation Technologies, which has a test track under construction in California and plans to connect Budapest, Vienna, and Bratislava with a hyperloop in the near future.

You can watch a video from BIG detailing how Hyperloop One’s system would work and be laid out below.

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Courtesy of BIG

Related Stories

Accelerate Live! | Jul 6, 2017

Watch all 20 Accelerate Live! talks on demand

BD+C’s inaugural AEC innovation conference, Accelerate Live! (May 11, Chicago), featured talks on machine learning, AI, gaming in construction, maker culture, and health-generating buildings.

| Jun 13, 2017

Accelerate Live! talk: Work in progress—How the office environment drives innovation, SageGlass (sponsored)

SageGlass CEO Dr. Alan McLenaghan reviews how biophilic design and new technologies, such as dynamic glass, create a greater connection between the built and natural environments in the office.

| Jun 13, 2017

Accelerate Live! talk: Next-gen materials for the built environment, Blaine Brownell, Transmaterial

Architect and materials guru Blaine Brownell reveals emerging trends and applications that are transforming the technological capacity, environmental performance, and design potential of architecture.

| Jun 13, 2017

Accelerate Live! talk: Incubating innovation through R&D and product development, Jonatan Schumacher, Thornton Tomasetti

Thornton Tomasetti’s Jonatan Schumacher presents the firm’s business model for developing, incubating, and delivering cutting-edge tools and solutions for the firm, and the greater AEC market.

| Jun 13, 2017

Accelerate Live! talk: The future of computational design, Ben Juckes, Yazdani Studio of CannonDesign

Yazdani’s Ben Juckes discusses the firm’s tech-centric culture, where scripting has become an every-project occurrence and each designer regularly works with computational tools as part of their basic toolset.

| Jun 13, 2017

Accelerate Live! talk: A case for Big Data in construction, Graham Cranston, Simpson Gumpertz & Heger

Graham Cranston shares SGH’s efforts to take hold of its project data using mathematical optimization techniques and information-rich interactive visual graphics.

| Jun 13, 2017

Accelerate Live! talk: Scaling change in a changing industry, Chris Mayer, Suffolk Construction

Suffolk’s CIO Chris Mayer talks about the firm’s framework for vetting and implementing new technologies and processes.

Great Solutions | Jun 6, 2017

Good vibrations: Portable tuned mass damper provides lightweight, cost-effective way to reduce structural vibrations

Developed by a team at Virginia Tech, the PTMD has been shown to reduce vibrations by as much as 75%.

Building Tech | Feb 23, 2017

Designing an inclusive, automated city

How can cities of the near future put an emphasis on equality while also reaping the abundant benefits of technological progress?

Sponsored | | Jan 31, 2017

From devastation to hope in Haiti

GF Construction, led by Charles and Jerry Fombrun, designed an industrial manufacturing development in Haiti that spans one million square feet, providing both a bank and a medical facility for employees, and housing for staff.