Clayco’s CEO and Chairman Bob Clark sees innovation as being at the center of what his firm does. It was one of the first GCs to use full-room computers, an IBM 3600 “that looked like a giant refrigerator,” he recalls. It was an early adopter of spreadsheet technology, using Prolog’s project management software.

In 2005, it started a full-service concrete subcontracting business that now has 1,000 employees and produces four million sf of concrete walls per year. Clayco was the first construction company to receive an FAA license to fly small unmanned aerial vehicles. In 2015, it launched Uplift Data Partners, a turnkey construction and real estate inspection service that uses drones. (It sold that business to PrecisionHawk.)

Clayco’s interest in drones led it to start Treehouse Adventures, a venture-capital entity that focuses on construction. Its investments include Ventana, a high-performance curtain wall fabricator and installer; and Drawn, a design group.

In 1993, Clayco formed its Mission Control team to bring project management out into the field. Mission Control started with a dozen people and now has one team member for every three project managers in the field. And the company’s “paradigm shift toward greater jobsite safety,” says Clark, got it involved recently in hard hat design with the Savannah (Ga.) College of Arts and Design.

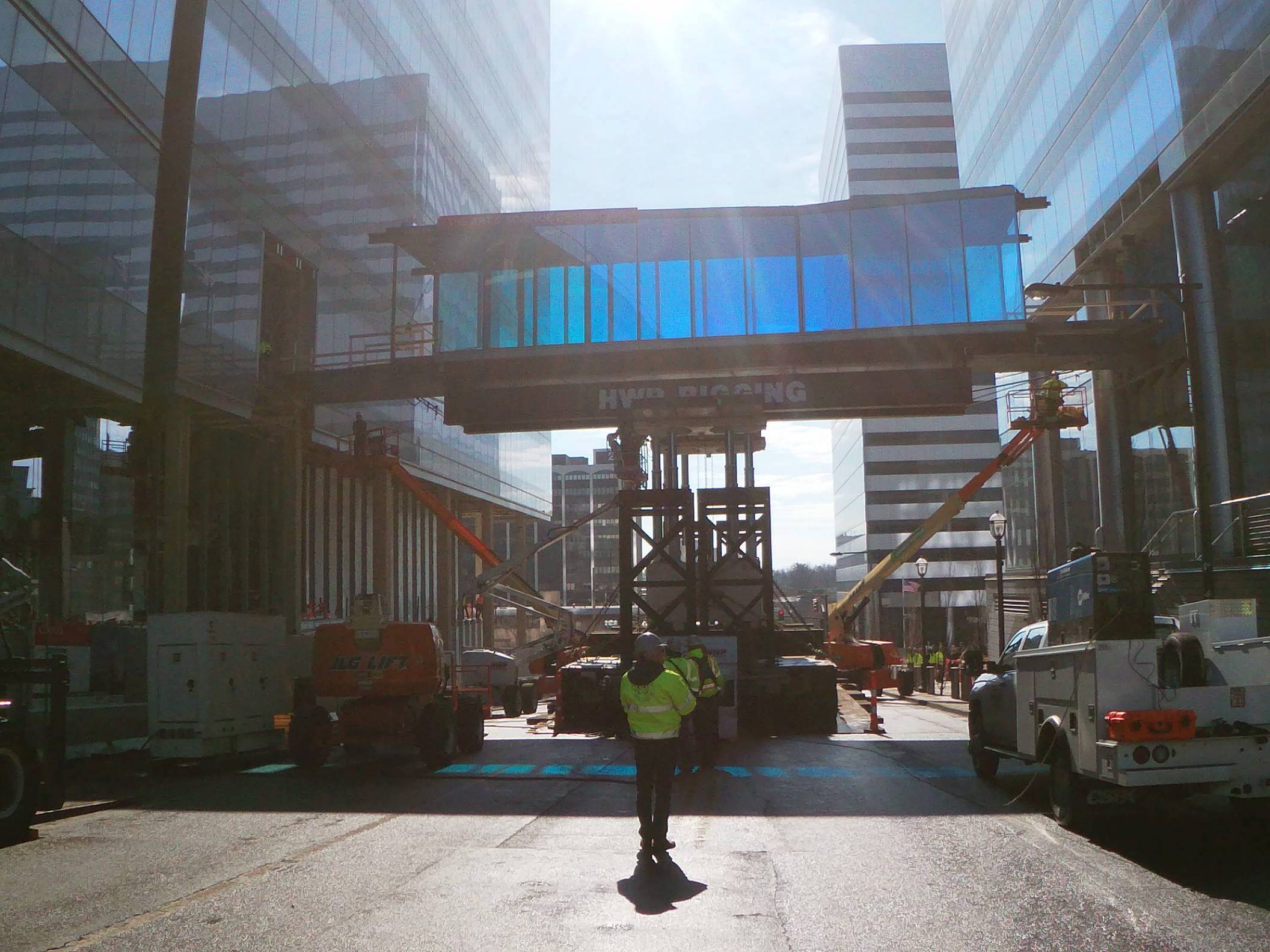

Its embrace of prefabrication allowed Clayco to build a bridge across a street in Missouri in a single day. Photo courtesy Clayco

Its embrace of prefabrication allowed Clayco to build a bridge across a street in Missouri in a single day. Photo courtesy Clayco

In June, the company combined its design businesses, Lamar Johnson Collaborative and BatesForum, providing Clayco with an integrated delivery model that Clark believes will “set a new standard.” Clark is looking ahead to see where else technology and better project management might give Clayco an edge.

He believes that modular construction will be required “on a mass scale” to counteract the industry’s aging workforce. Within three to seven years he expects robots to be doing more installation work.

ALSO SEE: Oracle’s replica of a construction jobsite creates an immersive environment for AEC professionals

Clark is a big proponent of BIM modeling and prefabrication. Last October, Clayco installed a bridge across a street in Clayton, Mo., in a single day by constructing the bridge’s steel-and-concrete components offsite. That delivery method saved local residents and businesses five months of impact on traffic.

For Pfizer’s 294,000-sf facility in Chesterfield, Mo., Clayco prefabricated the equivalent of two miles of lab walls, with conduit and pipe embedded.

Clark is also excited about artificial intelligence, albeit from a unique perspective of talent management to help employees map their careers and retirements. “We’re looking to build a talent management organization faster.”

For Pfizer’s 294,000-sf facility in Chesterfield, Mo., Clayco prefabricated the equivalent of two miles of lab walls, with conduit and pipe embedded. Photo courtesy Clayco

For Pfizer’s 294,000-sf facility in Chesterfield, Mo., Clayco prefabricated the equivalent of two miles of lab walls, with conduit and pipe embedded. Photo courtesy Clayco

Related Stories

AEC Innovators | Aug 9, 2019

Improving architectural designs through iteration

Computational design lets ZGF Architects see patterns that renderings and even models can’t show.

AEC Innovators | Aug 6, 2019

Structural engineer speeds skyscraper construction with novel building core design

With its Speed Core composite core wall system, Magnusson Klemencic Associates thinks it’s found a faster way to complete high-rise buildings.

AEC Innovators | Aug 5, 2019

Mace Group builds working on top of under-construction skyscrapers

The six-story factories eliminated the need for tower cranes, and increased productivity to the point where crews could complete 18 floors in 18 weeks.